22 de August de 2023

Discover our flight case manufacturing process

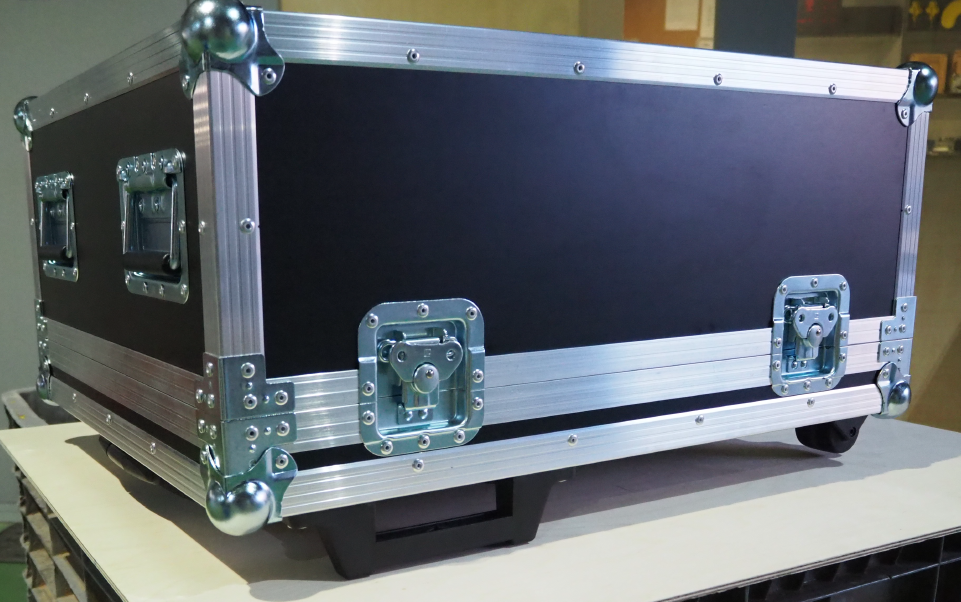

We show you our work process in the manufacture of flight cases and custom packaging. From the cutting of the boards to the interior protection

At Casemedia, we design and manufacture customized flight cases that guarantee total security and are specifically tailored to your requirements and needs.

You can customize the entire flight case, both the exterior and the interior, adding complements and compartments according to your needs. From wheels for mobility to foam and internal and external liners to protect delicate products. In addition, we offer various options of security locks, including the possibility of incorporating security systems such as keys or padlocks.

Our packaging, being custom-made, perfectly meets the expectations of our customers and is optimized for the different uses they wish to make of it.

The packaging is custom-made and optimized for different uses, Casemedia's purpose is to meet the needs of our customers. They are intended for different sectors, among which we highlight the aeronautical, audiovisual, industrial, events and medical-sanitary.

Flight cases have a variety of advantages. One of the most important is that they are 100% customizable. This not only means that they adapt perfectly to your product, instrument, material or equipment to be transported, but also that they adapt to your transport, storage and conditions needs. In addition, thanks to their exterior design with locks and handles, they provide great safety and ergonomics, and are more manageable and movable due to the use of wheels.

The raw materials used in the production process are of the highest quality. They guarantee safety during transport thanks to their resistance and the long life of the packaging and, therefore, of the product. In addition, their high resistance prevents damage to the contents during transport.

The manufacturing of our flight cases follows the following steps:

-

Preparation and cutting to size of the boards

Depending on the corporate image and the customer's preferences, we decide between bodyboard or birch plywood with PVC finish in different colors.

We make use of different types of materials to create the flight cases according to the requirements previously set. The customer has the possibility to design his own completely, adapting it to his needs, or he can also choose from our models available on the web.

Advancing in the customization of custom packaging, we offer the option of highlighting the corporate image by incorporating your logo both inside and outside the flight case.

-

Perfection in the cuts

The flight case cuts are 100% made to measure according to the design previously chosen by the customer. The pieces are delicately prepared so that, at the end of the process, everything fits perfectly.

-

Installation of aluminum reinforcements in its different angles

After completing the customer's custom design and cutting the panels, the next step is the installation of aluminum reinforcements. This step is essential, as it guarantees the panel's resistance to possible impacts, avoiding splintering. In addition, by reinforcing the angles, the overall structure of the flightcase is more solid.

These reinforcements are made of stainless steel, which allows the adaptation to temperature variations in any environment. It is also important to note that their weight is significantly lower than that of iron, which contributes to the lightness of the flight case.

-

Handle placement

When it comes to transporting a flight case, it is key to have handles that facilitate easy and comfortable handling. These handles are usually placed on the sides or on the top, adjusting also to the arrangement of the wheels, in case it has them. The material used in the manufacture of these handles may vary according to the size and purpose of the flight case.

-

Locks

Safety is paramount at Casemedia. Therefore, we advise and ensure that our customers choose the appropriate type of closure according to their intended use. Locking mechanisms can be either integrated or external. Within this variety, there are several types of locks such as butterfly type, padlock or key system, among others.

-

Installation of casters

The versatility of our manufacturing process allows for total customization, offering the customer the choice of whether or not to include casters in their flight case. Our casters are adaptable to various situations and have a load capacity of up to 1000 kg. Depending on requirements, 2 or 4 casters can be chosen to ensure optimal stability, either upright or at the rear for trolley type models. They can be fixed or swivel, with or without brakes, adapting to each specific situation.

-

Interior protection

Customization of interiors is commonplace for our customers. To achieve this, we use foams of different thicknesses and densities, including antistatic options, and use molds created using digital manufacturing techniques.

Our foams and fillers are based on a closed-cell cross-linked polyethylene structure. Their high flexibility ensures that no loose pores remain after machining, guaranteeing cleanliness. Despite their light weight, they maintain considerable strength and are suitable for laser cutting.

Importantly, the manufacturing process does not alter the chemical structure of the polyethylene, which facilitates recycling. These foams are completely custom-made and the different densities are adapted to the equipment, ensuring optimum and efficient protection.

If you want to design your own flight case or would like to adapt one of our models to your needs, do not hesitate to contact us through our website or by calling 954 380 624.

Latest news

20/08/2025

HPRC cases: extreme protection in every environment

At Casemedia, we work with market-leading packaging solutions designed to ensure the safety and durability ...

Learn more

23/07/2025

Flight cases for sound equipment: a guide to ideal protection

At Casemedia, we specialise in creating customised flight cases that guarantee the safety of your equipment ...

Learn more

24/06/2025

Aluminum packaging: efficiency, conservation and sustainability

In the field of product preservation and transport, packaging is an element that not only protects, but ...

Learn more